The gearbox transforms the power of the motor (torque); multiplying it to be able to start the march, climb slopes and carry weight in the car.

This is produced in the low gears to be reversed in the long ones.

The objective is to be able to adapt the force (torque) of the engine to the driving conditions and reduce consumption and pollution.

The four types of gearbox

In the section "Automobile technology course" the four different types of gearbox will be explained in detail ; manual in “H” , piloted / robotic , automatic (with converter) and continuously variable transmission (CVT), following the order of the program in the book of the same title.

On this occasion I propose to differentiate the four types from the point of view of use by the driver.

Manual gearbox

The silhouette of a Mercedes 300 SLR is used with these details in the animation:

- Technical implementation with longitudinal front engine and propulsion

- No. on the manual gearbox C. cm indicates that it has a certain number of ratios

- The clutch actuation is mechanical from its pedal E. am

- A 5-speed panel plus reverse is presented and the movement of the manual gear lever is seen in the shape of an “H” P. mH

The 4 types of gearbox (1/4)

Watch this video on YouTube

- The number of relationships No. was increasing, currently it reaches 7

- A detail to take into account to understand the handling of the other gearboxes is how the maneuvers are carried out in tight spaces

- In this manual gearbox it is done like this; the accelerator maintains the necessary driving force (torque) and adjusts the approach speed with the clutch in its mid-slip zone

- It seems difficult but once the skill is acquired, it is usually easy

|

Piloted or robotic gearbox

Let's see the explanations of this type of gearbox on the silhouette of a Ferrari Testarossa in this order:

- The implantation is central longitudinal motor and propulsion

- There is no clutch pedal , but there is clutch E. ap of piloted actuation

- The number No. of relations is 6, 7, ....,

- There is an electronic control for the clutch and gearbox C. e with information on the brake, accelerator, gear lever and other functional pedals of the engine and car displacement (RPM, km / h, ...)

- You can see the gear lever position template:

- "P" ; parking, "R" ; reverse, "N" ; Deadpoint

- "D" ; automatic operation, forward relationships are inserted without driver intervention

- "S" ; sequential; a "touch" forward or backward on the lever gives the order to raise or lower a ratio, the lever returns to the center. Going up and down can be as seen in the image or vice versa according to brands. These actions can also be done with controls from the steering wheel according to models

The 4 types of gearbox (2/4)

Watch this video on YouTube

- E. ap ; It is the clutch operated by electronic control C. e

- C. cp ; It is the piloted gearbox, like a manual gearbox in which the “H” is made by the electronic control C. e according to the positions of the gear lever:

- P. SD ; sequential positions S and automatic D

- E. ap ; It is the clutch operated by electronic control C. e

- Parking maneuvers require attention until you get into the habit because the necessary speed and the clutch engagement must be controlled simultaneously with very slight movements of the accelerator, which acts on the engine and the clutch, the latter through the electronic control C. e

In the image a normal clutch has been represented, with piloted drive.

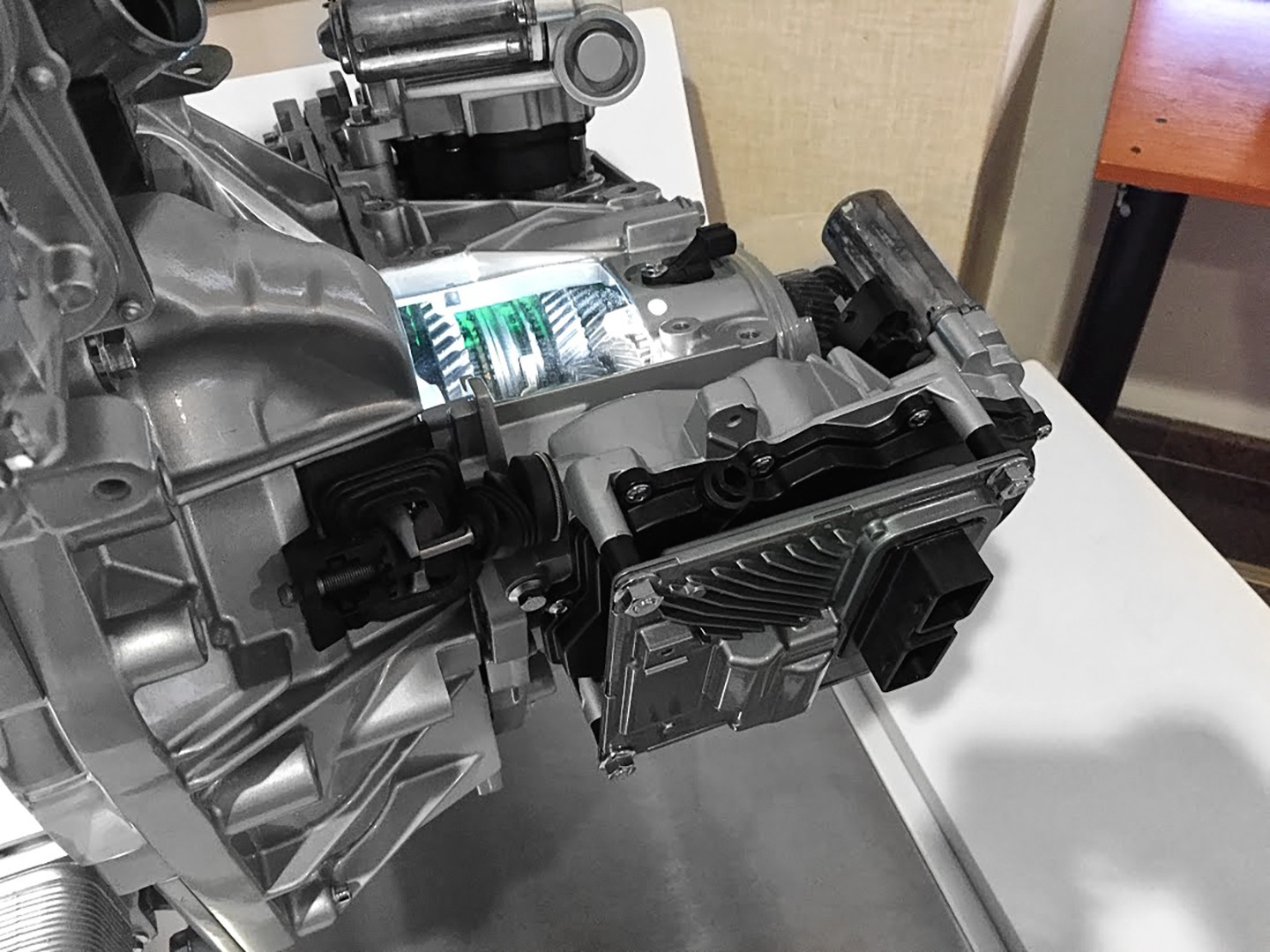

The most common thing in the piloted / robotic gearbox is to use two clutches, one for odd ratios and the other for even, dry or oil bath.

Operation can be electrohydraulic or fully electronic.

Automatic gearbox with torque converter

The silhouette of the car in the image is a Bentley Continental and the animation follows this order:

- The implementation is longitudinal front engine and 4 × 4

- There is no clutch or pedal; in its place is the torque converter C. p

- The number of relationships now reaches 9

- The electronic control of the gearbox C. e , has information on the brake, accelerator, gear lever and the other functionalities of the car

The 4 types of gearbox (3/4)

Watch this video on YouTube

- The positions of the gear lever are these, although they seem like those of the piloted box, the technical operation is very different:

- "P" ; parking, the box is locked, "R" ; reverse, "N" ; Deadpoint

- "D" ; automatic operation

- "S" ; sequential; a "touch" forward or backward on the lever gives the order to raise or lower a ratio, the lever returns to the center. There may also be controls on the steering wheel depending on the models

- C. p ; torque converter, is the connection between the motor and the gearbox. It is, in a simple way, two turbines very close to each other, one is attached to the engine and the other to the gearbox. They are in a sump with pressurized oil. Turning the engine turbine drags that of the box with some slip. Its operation is hydraulic, there is no physical contact. Between the two turbines there is another with a specific geometry that multiplies the force (torque) of the engine up to half RPM, from this fact it derives the name of torque converter C. p

- C. ca ; automatic gearbox, the technology of insertion of the relationships is by means of discs in oil bath and is done with electronic control currently C. e according to the positions of the gear lever

- P. Ds automatic D and sequential S positions ; by concept the automatic box was designed to circulate in "D" , then it has evolved with more possibilities. According to brands and models, from the sequential position S , a ratio can be selected or the automatic actuation can be limited to that gear

- Parking maneuvers are simple because the drag effect of the converter C. p moves the car to the release of the brake pedal, simply insert "D" or "R" and the brake pedal to control the movement

- Before having the possibility of sequential use S , the automatic gearboxes had a different position panel, which I call a sliding panel and you can see it at the end of the animation, these are the positions and explanation:

- "P" , "R" , "N" and "D" ; They are the same that have been explained before, with the particularity that in "D" all the relationships act automatically, which are usually one more than the next number, 4 in the image so the box would be 5 speeds

- The other positions from "4" to "1" indicate until which ratio the automatic operation is authorized; in “4” the 5th would not enter, in “3” it would be automatic until the 3rd and in “1” it would circulate permanently in 1st

- The “W” and “S” controls are used to select the winter or ice (“winter” = winter) and performance positions respectively. In “W” the gear starts in 2nd or 3rd gear and changes are made extremely smoothly. In "S" the engine runs at a higher RPM and reduces before gear when decelerating

The fact that you need more positions in addition to “D” to circulate is mainly to be able to reduce speed effectively on long descents, either with the slide lever or in a sequential position.

Some automatic sliding boxes have the "over drive" button or knob, OD.

It allows to cancel the automatic operation of the last relationship when pressed.

It has nothing to do with the "over drive" used in the manual gearbox.

CVT continuously variable gearbox

For this type of gearbox I will use the silhouette of the Subaru XV with this order of animations:

- The implementation is with a longitudinal front engine and 4 × 4

- There is no clutch or pedal; in its place is the torque converter E. cp

The 4 types of gearbox (4/4)

Watch this video on YouTube

- The number of relationships is infinite since there is a continuous variation from the shortest to the longest without transitions

- Currently the control is electronic C. e , with information on the brake, accelerator, gear lever and the other functionalities of the car

- The gear lever positions are as follows:

- "P" ; parking, the box is locked, "R" ; reverse, "N" ; Deadpoint

- "D" ; automatic operation, the speed of the car is increased without the increase in engine RPM being proportional. As the engine accelerates more the RPM rises and the process of continuous variation is continued from those RPM

- "S" ; selection of a predetermined number of ratios (6, 7, 8, ...), simulating a gearbox with sequential drive. This possibility did not exist in the first continuously variable boxes

- E. cp ; It is the connection system between the engine and the gearbox. The image represents the torque converter E. cp , the most widely used. It can also be done with a piloted or electromagnetic clutch

- CVT ; continuously variable (transmission) box

- P. D (infinite) ; with the lever in "D" you have infinite continuous relationships

- P. S (ppf) ; sequential actuation simulation with continuously variable system presets

- The parking maneuvers depend on the connection system between the engine and the CVT box; with converter has been explained in the automatic gearbox and with piloted clutch in the piloted / robotic gearbox, with electromagnetic clutch it would be similar to the latter

Initially the CVT box had the positions P - N - R - D - L ; the latter involves more engine RPM for prolonged acceleration, ups and downs.

:max_bytes(150000):strip_icc()/CVT-58e526803df78c5162b323c9.jpg)

Comments

Post a Comment